《 Product Highlights 》

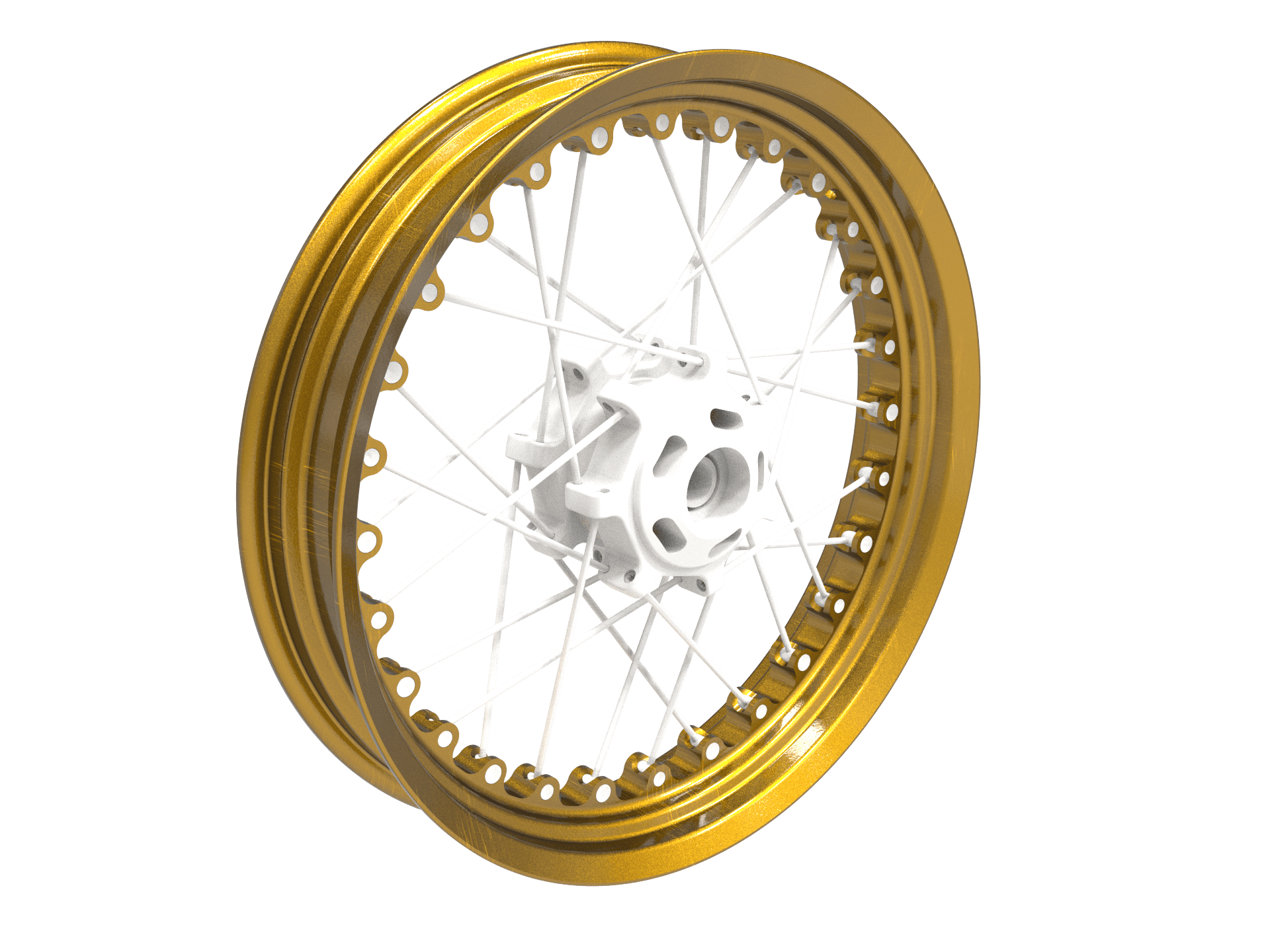

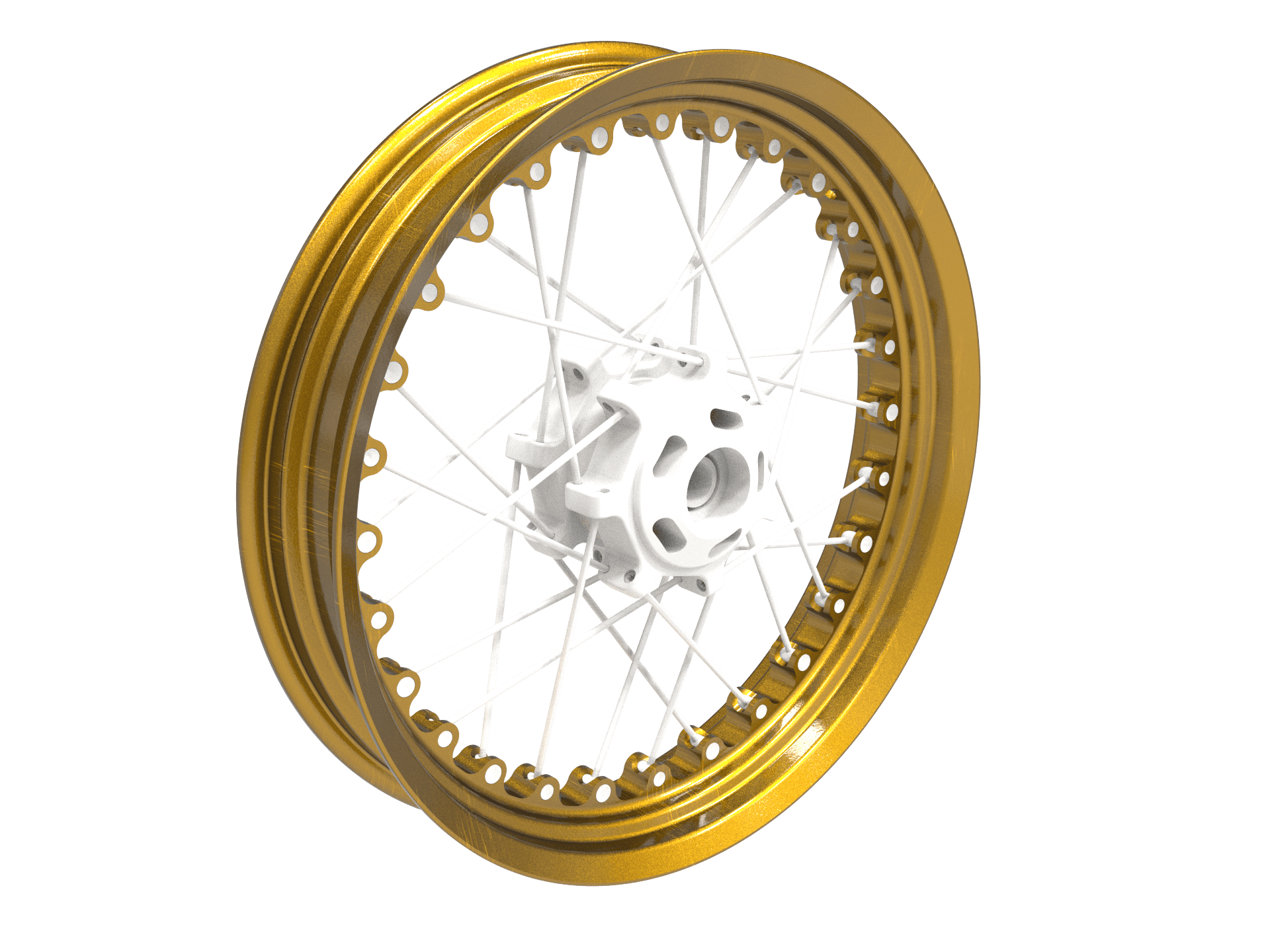

The advantages of forged wire frames are the high material density and strength, capable of withstanding vertical and lateral torsion forces, surpassing the overall structure of conventional iron wire frames. In addition to its high strength, the material's elasticity and density are higher compared to original iron frames, resulting in a lighter weight overall, with superior strength and durability than the latter.The innovative design breaks away from the traditional method of drilling holes into the frame wall for wire attachment. The new generation of airless forged wire frames not only achieves top-tier quality but also challenges conventional thinking. ”DOUBRO“ forged wire wheels are manufactured in Taiwan with a full production process, possessing international professional certifications, meeting the highest standards of safety coefficient verification. Choosing a local manufacturer in Taiwan will be your best option.

《 Product Information 》

(1)One-piece Forging

Adopting a new precision forging process, made from heat-treated "AL" grade 6061, the integral forging offers excellent sealing. It embodies the classic beauty of "DOUBRO" combined with the dynamic performance and safety of the new generation. Through composite precision processing, strict ISO inspections, and compliance with international certifications, it is durable and long-lasting. The wire fixed beans come in a variety of colors and installations, offering freedom to customize the forged wire frames in 12, 17, 18, 19, 20, and 21 inches, providing versatility for different vehicle models.

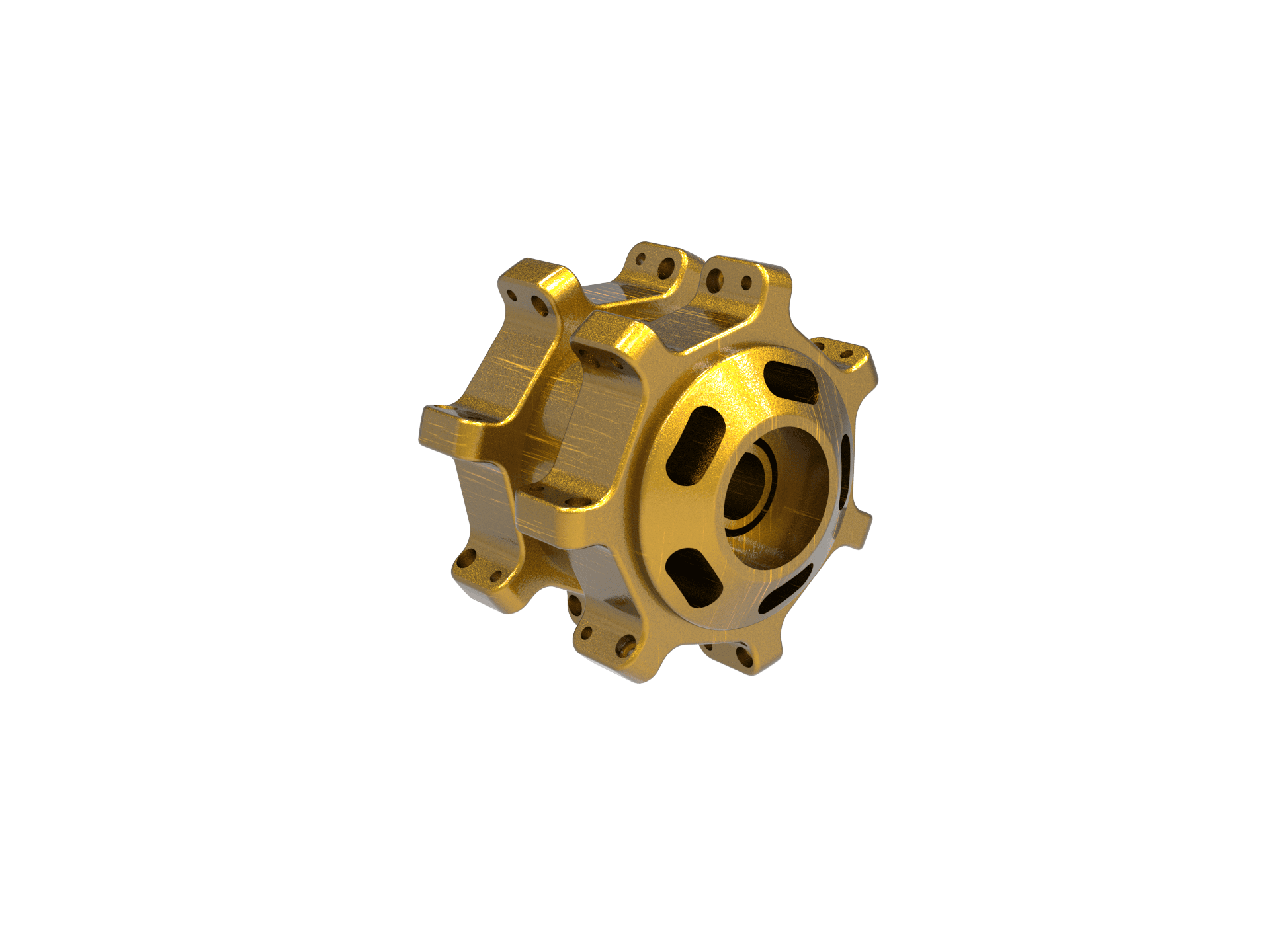

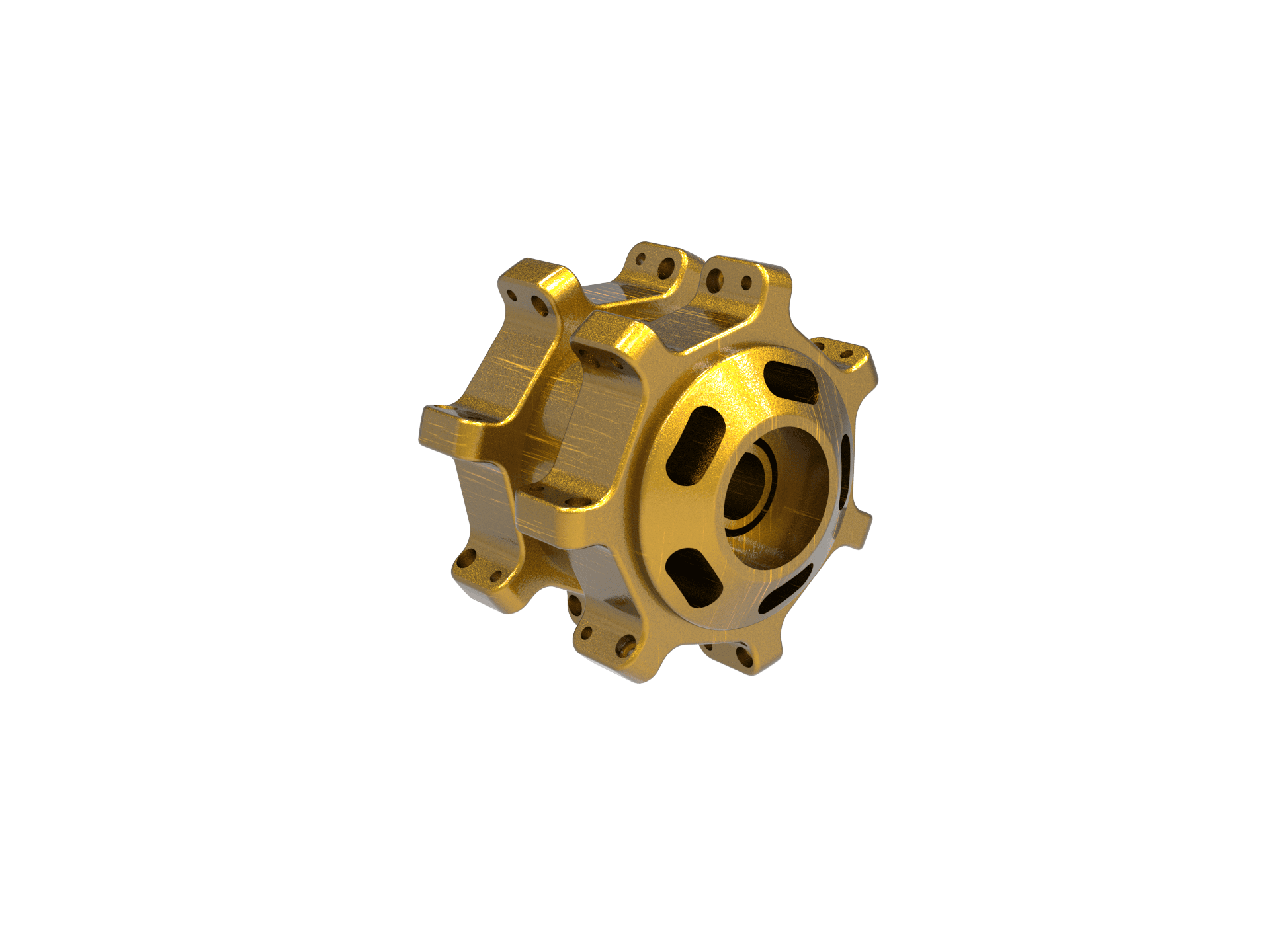

(2)Patented Design

Providing optimal distribution of wire and wheel frame tension, "DOUBRO" has designed a patented integral hub capable of withstanding maximum tensile strength and wheel frame rolling inertia. Made from aerospace-grade aluminum alloy and subjected to composite precision processing, it achieves a one-piece molded component. Finished with an anodized corrosion-resistant surface, it offers a variety of colors to choose from. Paired with imported bearings and seals, it provides the best dynamic functionality and airtightness.

(3)Using aerospace-grade SUS

The dual-width steel wire strips, compared to the original, have a higher strength and are formed with exclusive processes for resistance and high density. They are galvanized for corrosion resistance. The front and rear wheel widths are designed by "DOUBRO" to achieve the best angle of mutual tension, using a universal design. This promotes the concept of general maintenance and achieves sustainable environmental protection. No longer is there a need to search for special tools to tighten screws; simply replacing a single steel wire strip makes replacement effortless.

(4)Alloy "AL" Pins

The steel wire fixed pins are the most crucial part of "DOUBRO" exclusive design, with patented angle steel wires that enhance the tension and strength of the steel wires. The steel wire fixed pins are screwed into both ends in a transverse direction (parallel to the wheel axle), eliminating the traditional method of drilling holes in the aluminum rim to secure the steel wires, ensuring the integrity and airtightness of the tire.

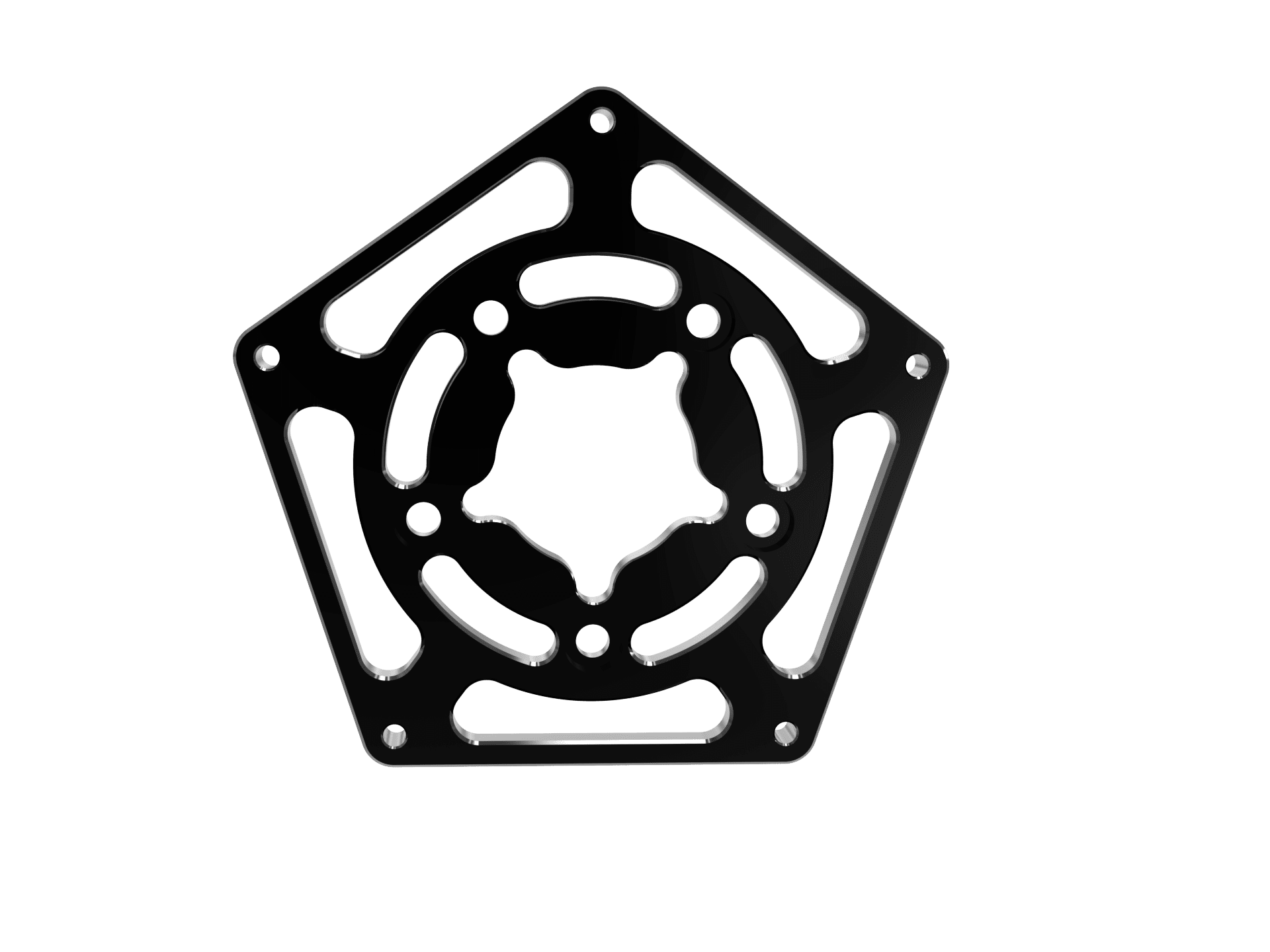

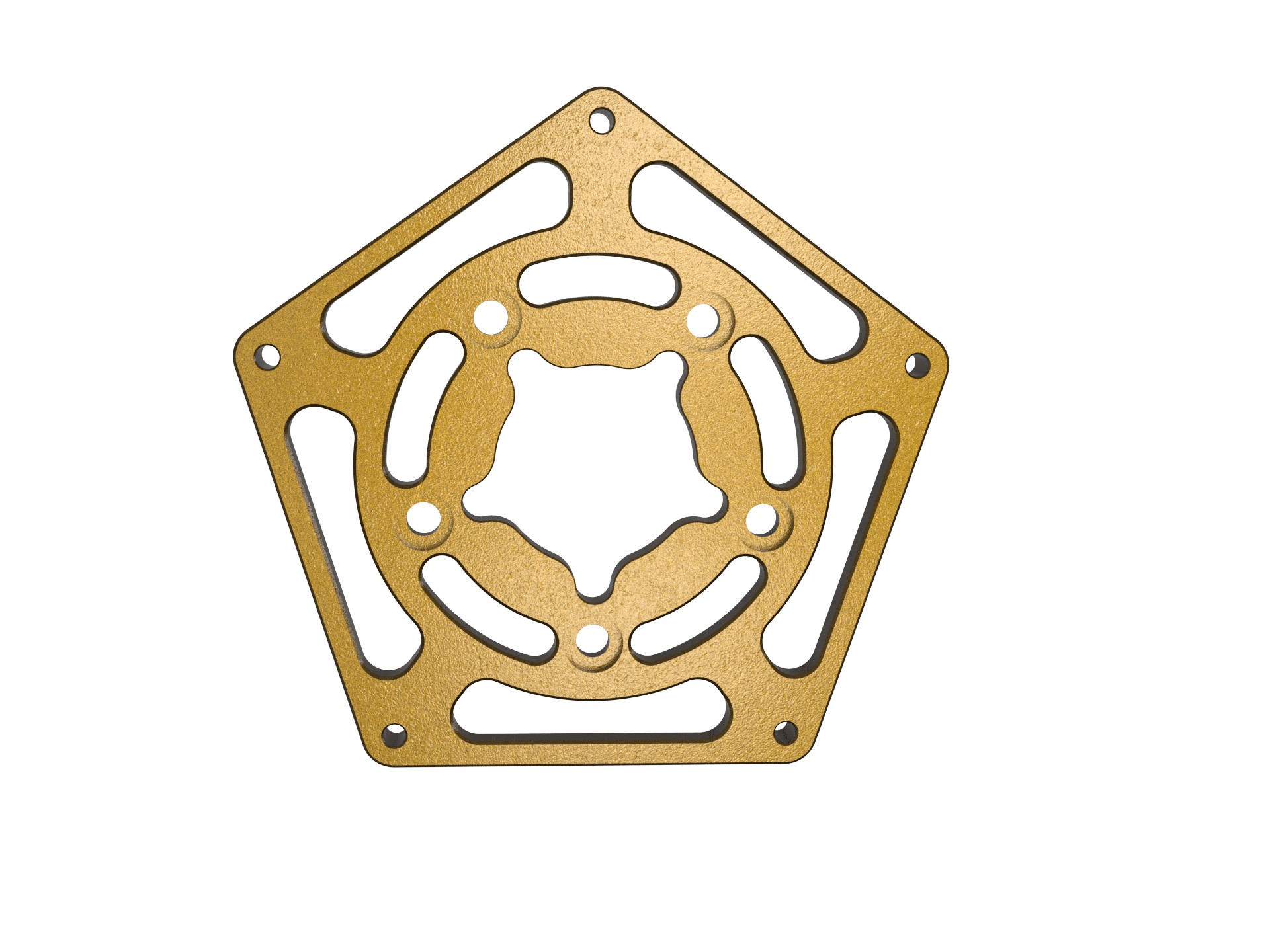

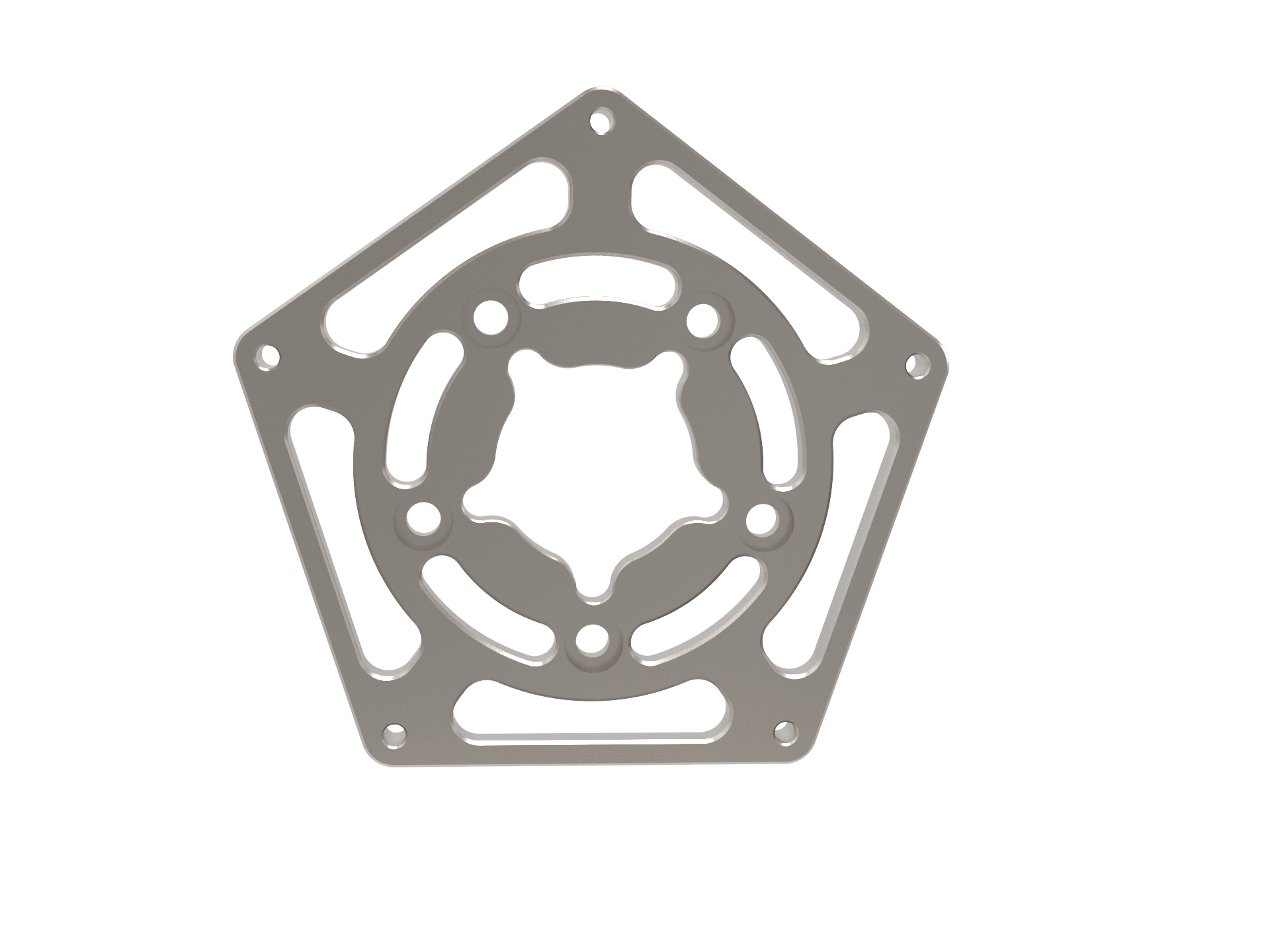

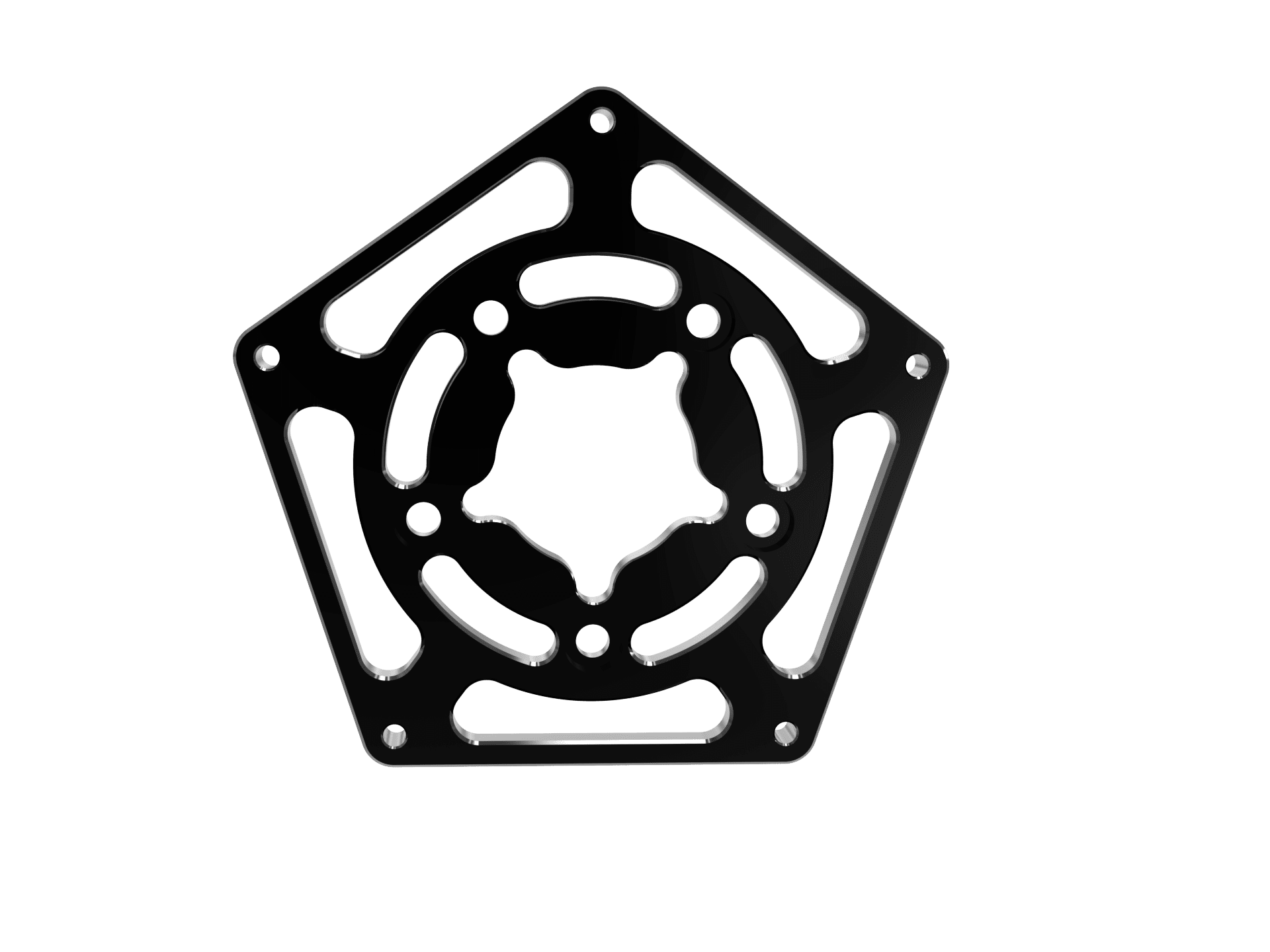

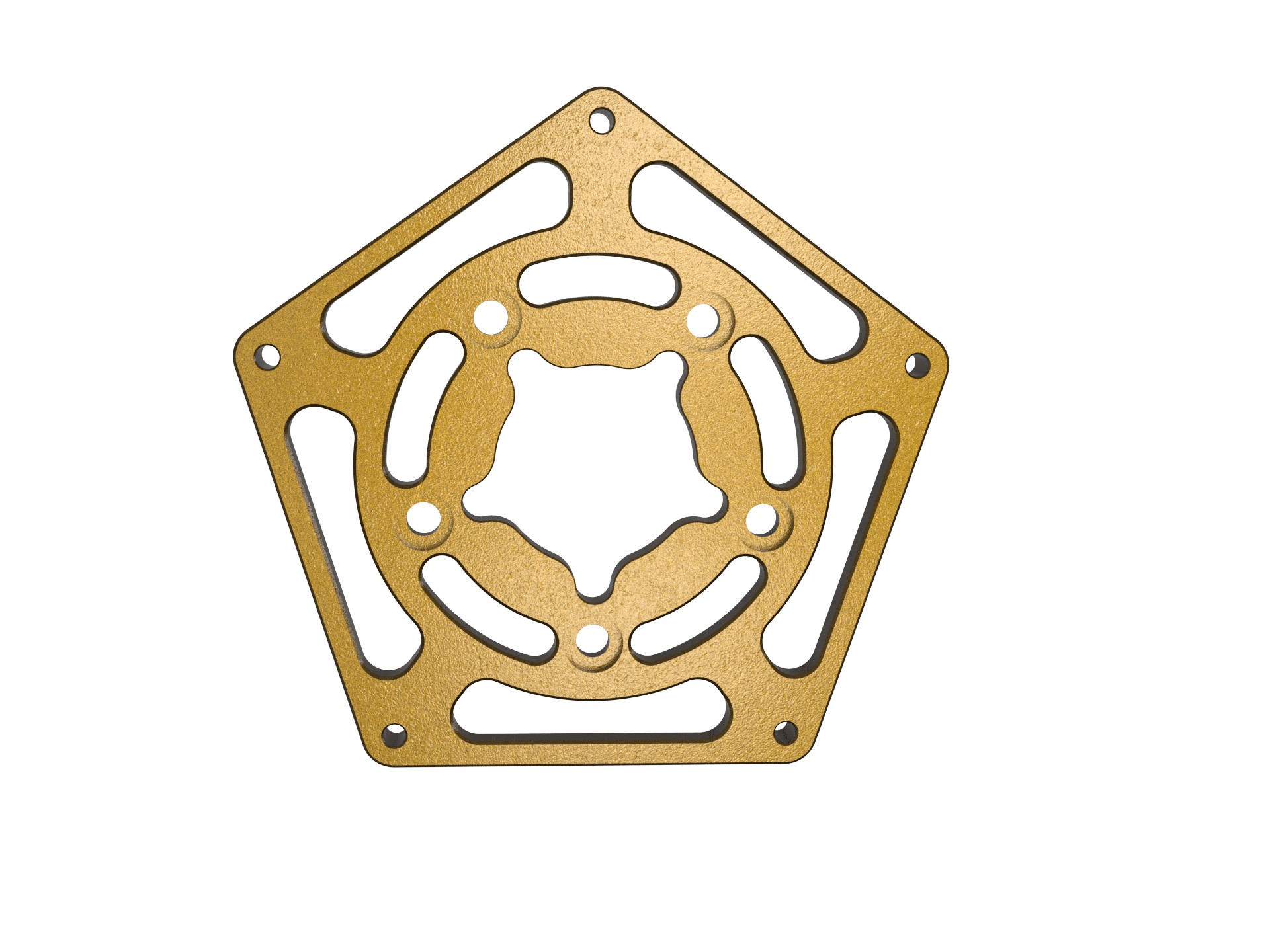

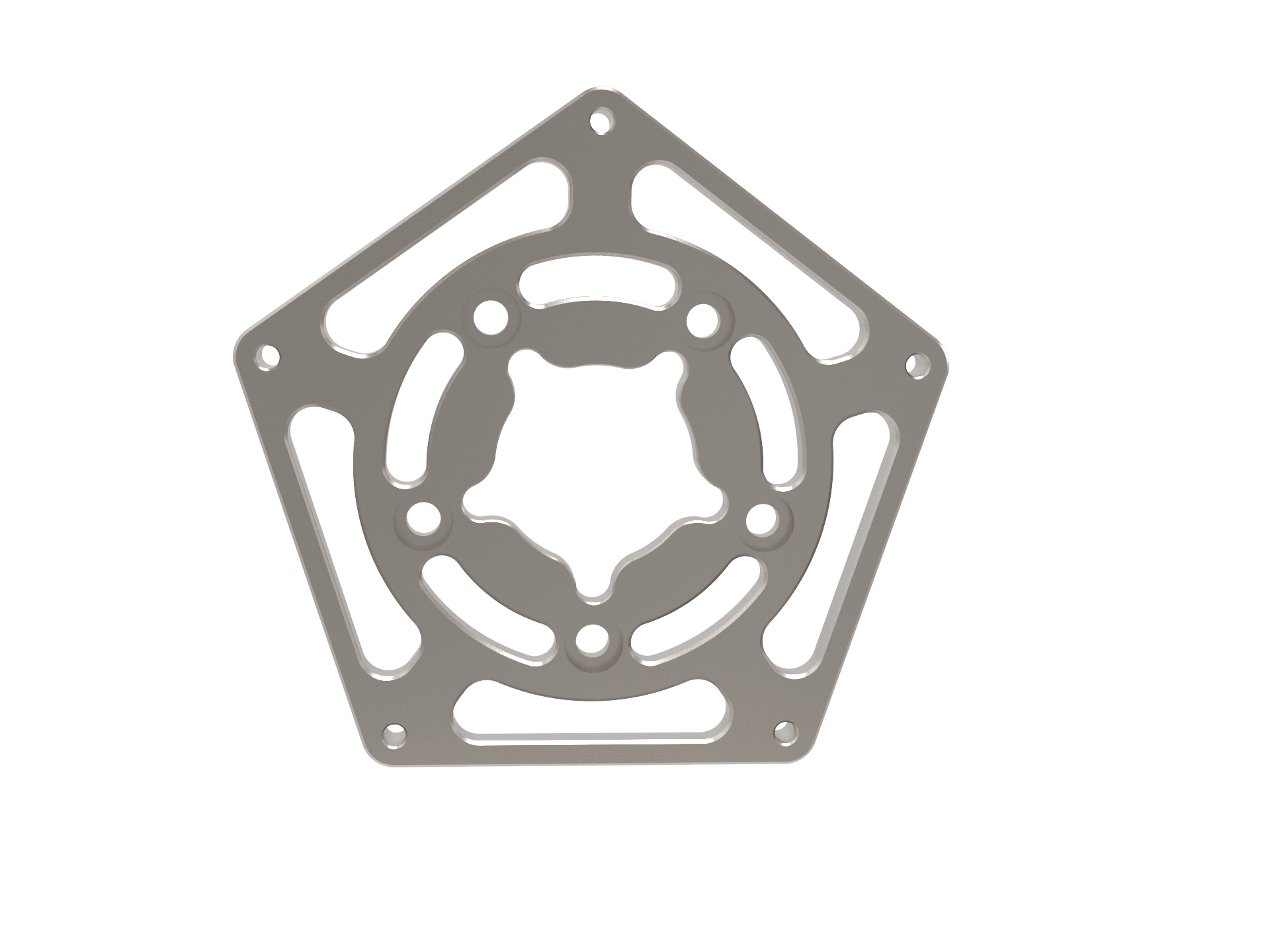

(5)Disc adapter brackets

The DOUBRO forged wire wheels and original brake systems (front single or dual floating disc, rear disc) can be directly installed without modification. Even ABS versions can be reinstalled in their original positions. The brake disc mounting brackets are made of aerospace-grade alloy to create a high-strength and safe braking system. The mounting screws are made to SCR10.9 specifications to withstand high-strength loads, ensuring stability even during high-speed intense operations. Additionally, you can upgrade to titanium alloy screws for higher strength and lightweight, giving riders a different visual experience (please note that some models may not have disc mounting brackets, please check before purchasing).

Adopting a new precision forging process, made from heat-treated "AL" grade 6061, the integral forging offers excellent sealing. It embodies the classic beauty of "DOUBRO" combined with the dynamic performance and safety of the new generation. Through composite precision processing, strict ISO inspections, and compliance with international certifications, it is durable and long-lasting. The wire fixed beans come in a variety of colors and installations, offering freedom to customize the forged wire frames in 12, 17, 18, 19, 20, and 21 inches, providing versatility for different vehicle models.

(2)Patented Design

Providing optimal distribution of wire and wheel frame tension, "DOUBRO" has designed a patented integral hub capable of withstanding maximum tensile strength and wheel frame rolling inertia. Made from aerospace-grade aluminum alloy and subjected to composite precision processing, it achieves a one-piece molded component. Finished with an anodized corrosion-resistant surface, it offers a variety of colors to choose from. Paired with imported bearings and seals, it provides the best dynamic functionality and airtightness.

(3)Using aerospace-grade SUS

The dual-width steel wire strips, compared to the original, have a higher strength and are formed with exclusive processes for resistance and high density. They are galvanized for corrosion resistance. The front and rear wheel widths are designed by "DOUBRO" to achieve the best angle of mutual tension, using a universal design. This promotes the concept of general maintenance and achieves sustainable environmental protection. No longer is there a need to search for special tools to tighten screws; simply replacing a single steel wire strip makes replacement effortless.

(4)Alloy "AL" Pins

The steel wire fixed pins are the most crucial part of "DOUBRO" exclusive design, with patented angle steel wires that enhance the tension and strength of the steel wires. The steel wire fixed pins are screwed into both ends in a transverse direction (parallel to the wheel axle), eliminating the traditional method of drilling holes in the aluminum rim to secure the steel wires, ensuring the integrity and airtightness of the tire.

(5)Disc adapter brackets

The DOUBRO forged wire wheels and original brake systems (front single or dual floating disc, rear disc) can be directly installed without modification. Even ABS versions can be reinstalled in their original positions. The brake disc mounting brackets are made of aerospace-grade alloy to create a high-strength and safe braking system. The mounting screws are made to SCR10.9 specifications to withstand high-strength loads, ensuring stability even during high-speed intense operations. Additionally, you can upgrade to titanium alloy screws for higher strength and lightweight, giving riders a different visual experience (please note that some models may not have disc mounting brackets, please check before purchasing).